7 Steps to a Bubble-Free and Flawless Cure

Click here to purchase our epoxy resin!

Few things exist that are more satisfying than creating a bubble-free resin piece that is flawlessly cured. On the contrary, few things are more frustrating than working tirelessly on a piece, and the result being less than satisfying. No artist enjoys putting time, effort, and passion into a piece, and it coming out sticky, covered in a layer of jelly-like goo, or filled with bubbles.

So, whether you have worked with resin before, and want to perfect your craft, or have recently learned of this mystifying medium and are attempting to build the courage to create your own piece: here is our guide to ensure that your projects reflect the vision that you start with.

- TEMPERATURE IS KEY. The temperature of the workspace, and resin itself, is key. The workspace should be between 72°-85°F, the closer to 78°, the better.

-

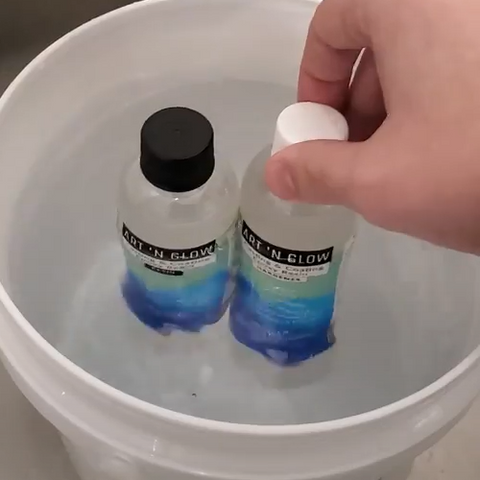

WARM YOUR RESIN & HARDENER. If the resin is cool, use a warm bucket of water and place the resin and hardener bottles into the warm water. This will prevent microbubbles. The working time* of the resin mixture will go from 45 minutes, down to 30 minutes. This is because the resin mixture is thermosetting, and with increased temperature, the curing process will begin sooner than usual.

(*Working time is the time you have to mix and pour the resin mixture once the hardener and resin meet in the same cup.)

-

CAREFUL POURING. When pouring either the resin or hardener, carefully pour down the side of the measuring cup. Pouring from high above the measuring cup can result in air bubbles.

- 1:1 RATIO BY VOLUME. Double check that the resin and hardener are exactly a 1:1 ratio of resin to hardener by volume.

-

MIX SMOOTHLY & THOROUGHLY. When mixing, mix smoothly, thoroughly, and consistently to avoid adding air bubbles. (To avoid adding air to the mixture, press the stirring utensil to the bottom of the cup while mixing.)

-

REMOVE BUBBLES. After the resin and hardener is mixed and poured, wait about two minutes. Then, to remove any air bubbles, use an artist's torch, heat gun, kitchen torch, lighter, toothpick, or straw to remove bubbles. (Keep checking over the next 1-2 hours to make sure that additional bubbles do not appear.)

- MILKY MAY MEAN LOW TEMP. Last tip: If the resin and hardener are ever milky or cloudy, this is a good indicator that the temperature of your resin is too low.

Working with resin can seem intimidating at first. However, once you understand the elements of a successful pour, it is easy to retrace your steps and see what went wrong whenever issues arise.

We hope that these steps give you the confidence to jump into working with resin, if you haven't already. If you already have experience working with resin, we hope that these steps serve as a guide so that every pour you do leaves you satisfied with your work and inspired to create more!